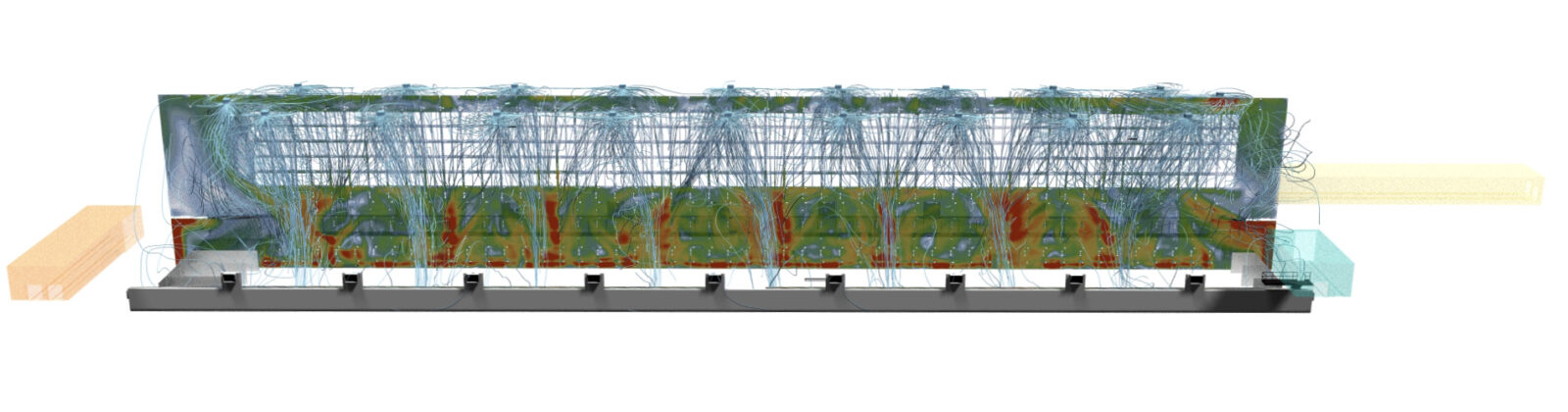

Cubit’s Fluid Dynamics Division conducted an in-depth analysis of the air conditioning system of a large industrial site to optimize the air intake and control of possible suspended particles throughout the entire site area. The study aimed to evaluate the effectiveness of the solution under realistic operating conditions, both in total and partial usage of the spaces.

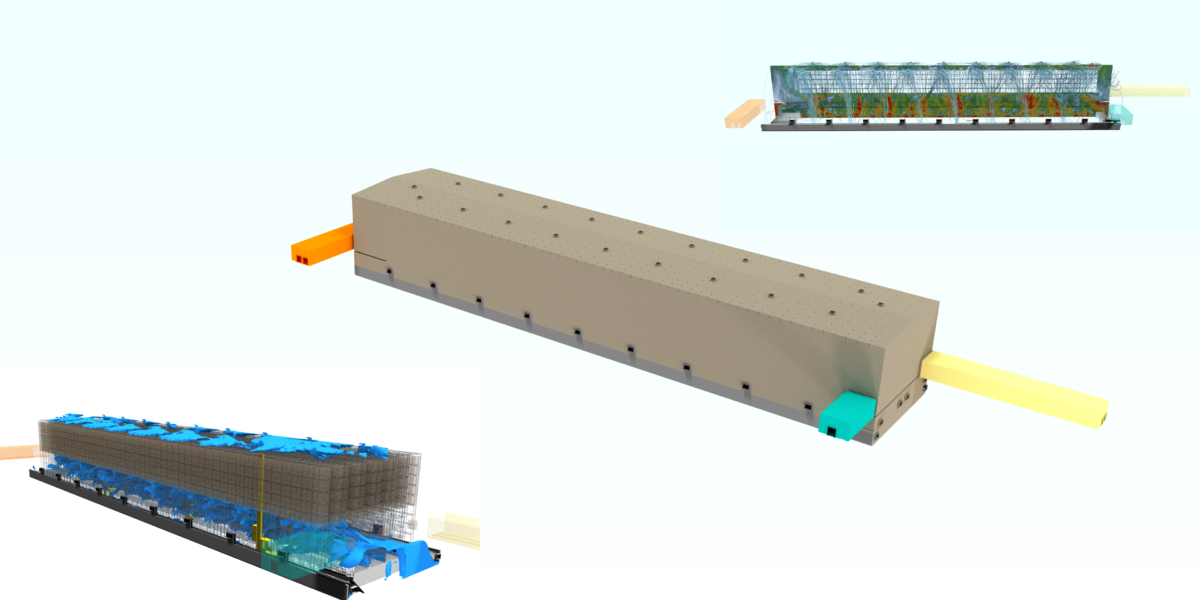

The generation of the Digital Twin, a longer and more complex process compared to typical automotive and nautical cases, allowed for an accurate replication of the details of the studied building.

The high level of detail represented in the model facilitated an effective assessment of the impact of each geometric feature on the airflow characterizing the problem, providing reliable and high-quality results.

Once the reference configuration was characterized, a sensitivity analysis was conducted on the position, size, and power of the devices composing the air conditioning system. This analysis aimed to optimize the new system by modifying the previous setup to maximize its effectiveness.

Such analyses demonstrate that numerical optimization coupled with CFD analysis enables a significant improvement in the efficiency and effectiveness of HVAC systems, both in industrial and domestic settings. It provides designers and builders with tools to address the requirements introduced by the energy transition, as improving efficiency minimizes energy consumption and the environmental impact of the building.

Having a realistic Digital Twin opens the door to the implementation of advanced air control strategies, including IoT devices for continuous monitoring of operational conditions and the actual fluid dynamics situation. This further enhances efficiency compared to conventional systems, meeting the demands of an increasingly digital world that is mindful of the environmental impact of new and existing constructions.